Innovative and functional methods

We produce prototypes by the sintering process of plastic or metal powders

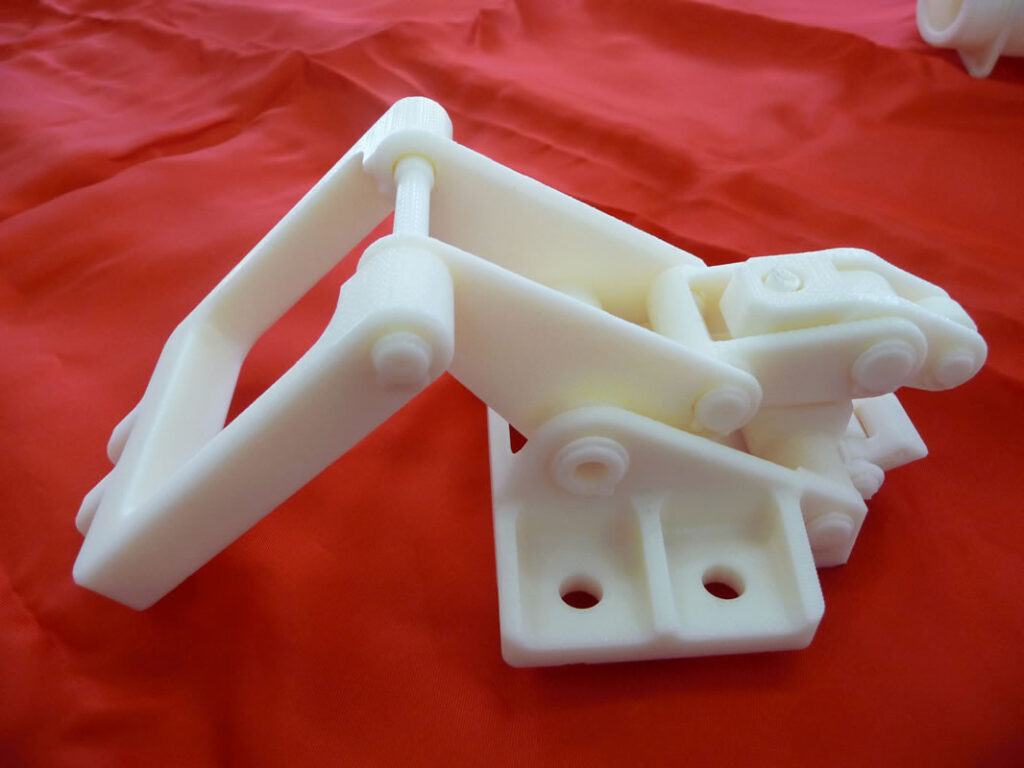

Among our solutions and services for the aerospace and other industries, we also offer rapid prototyping of components. Our experienced staff produces prototypes using an excellent method: sintering plastic or metal powders. This process allows us to produce the objects by placing the powder inside a specific mould. By heating it to a high temperature, but without reaching the melting temperature of the chosen material, we can produce demonstration and/or functional prototypes. Prototypes can be of different shapes and sizes. It was Highftech Engineering that produced the first laser sintering component for the International Space Station (ISS). For ESA, on the other hand, we studied how additive manufacturing technologies could be used on habitation bases installed on other planets.

Better production and cost savings

A well-made prototype is always an asset not to be underestimated

Highftech Engineering works alongside companies and industries of various kinds, producing high-quality prototypes. Our 3D prototypes are manufactured with great care, guaranteeing each customer high levels of precision and quality. Our rapid prototyping service can optimise in particular the production and advanced manufacturing processes of all instruments and applications used in aerospace and beyond. In every context, it offers many advantages, from cost reduction to improved manufacturing processes. Prototyping also makes it easier to produce better and better components (e.g. lighter and more dynamic), without increasing production costs. Contact us for more information and a personalised consultation.